Professional Haloo Vending Machine Manufacturer & Supplier.

durable snack machine series for red wine

1. The design of Haloo food dispenser machine has been optimized. Many factors have been considered in terms of thermal properties, surface finish, lubrication, friction, and noise.

2. The quality of this product is far more superior to that of other brands.

3. The product meets the set industry standards in all respects, including durability, performance, function, etc.

4. This quality product will keep its original shape for years, giving people extra peace of mind because it's very easy to care for.

| Description | Index |

| Model | HL-DRE-10C |

| Outside Dimensions | 1920*1180*850(mm) |

| Color | White,black |

| Merchandise type | Maximum about 80choices |

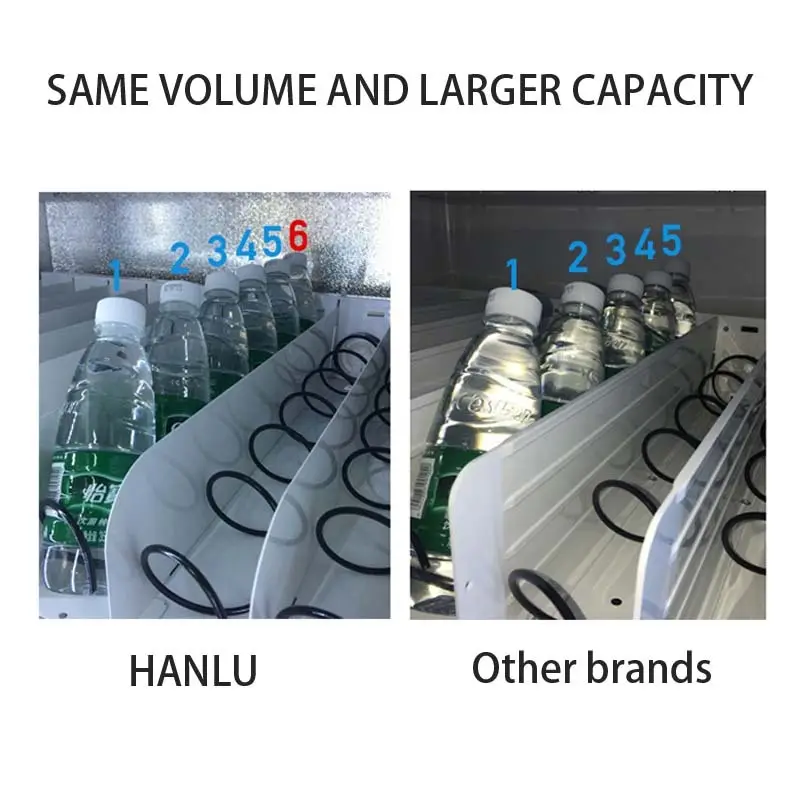

| Capacity | 360-1000pcs |

| Storage capacity | 7drawers, 10channels |

| Power & voltage | 550W, 110V-220V, 50/60HZ |

| Weight | 320kg |

| Payment System | Bill, coin, coin dispenser, and cashless payment. |

| Network Mode | GPRS |

| Standard interface | MDB/DEX |

| Screen | Without screen |

* Partial parameter support customization, more detail please connect with us.

◪ Belt delivery design, can sale more kind of goods.

◪ Durable Stainless steel keypad.

◪ Inside modular design, easy to update, operate and maintain.

◪ Shopping trolley function, more flexible to select goods.

◪ High capacity to storage merchandise, more convenient.

◪ Salable goods: bottle packed/box packed/canned beverage, snack and condom, slave machine is available.

◪ Two lighting bars installed in two sides, attract consumers and convenient to shopping.

◪ Customized language display.

◪ Remote control system with management software, easy to check information and management in real time.

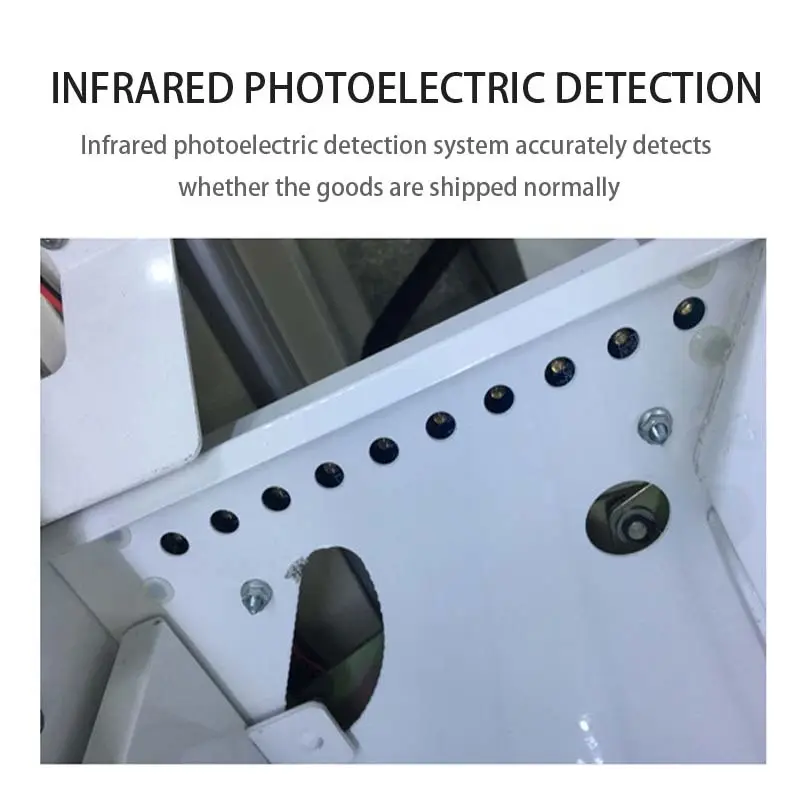

◪ The cargo port and inventory are completely isolated, with anti-theft device design.

◪ With power-off protection device, which can restore the date after restart.

◪ The powerful cloud service shows the sale information, running status of each vending machine from the internet anytime and anywhere.

◪ Support GPRS remote management system.

Company Features

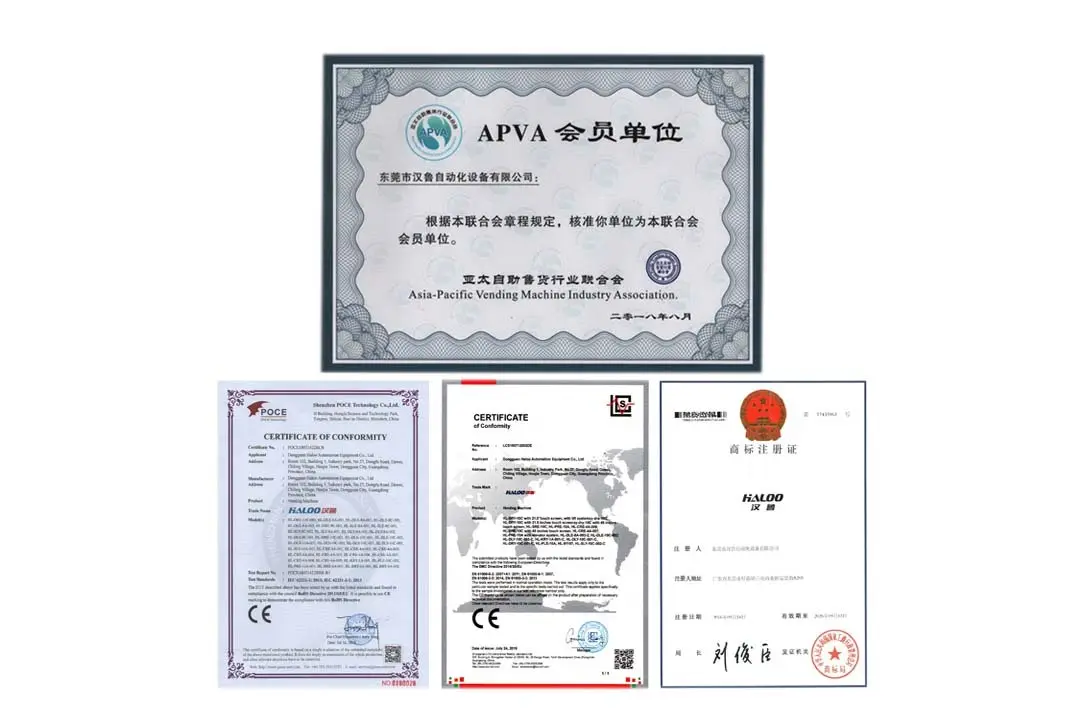

1. The business of Haloo Automation Equipment Co., Ltd has a global reach with production sites all over the worlds.

2. Our factory is equipped with cutting-edge manufacturing facilities. Leveraging on these machines, we are able to achieve a relatively high automation level and increased productivity.

3. We have strictly implemented sustainability practices. During our production, we consume our energy more efficiently, which can minimize our carbon footprint. Under the concept of customer-orientation, we will make every effort to offer more quality products and offer considerate service to the customers and society. We engage pro-actively with suppliers in an effort to ensure ethical practices and help our customers find sustainable solutions to critical issues bringing about real changes.

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.