Professional Haloo Vending Machine Manufacturer & Supplier.

cost-effective recycling machines factory direct supply for lucky box gift

- Haloo strives to explore a humanized and diversified service model to provide all-round and professional services for customers.

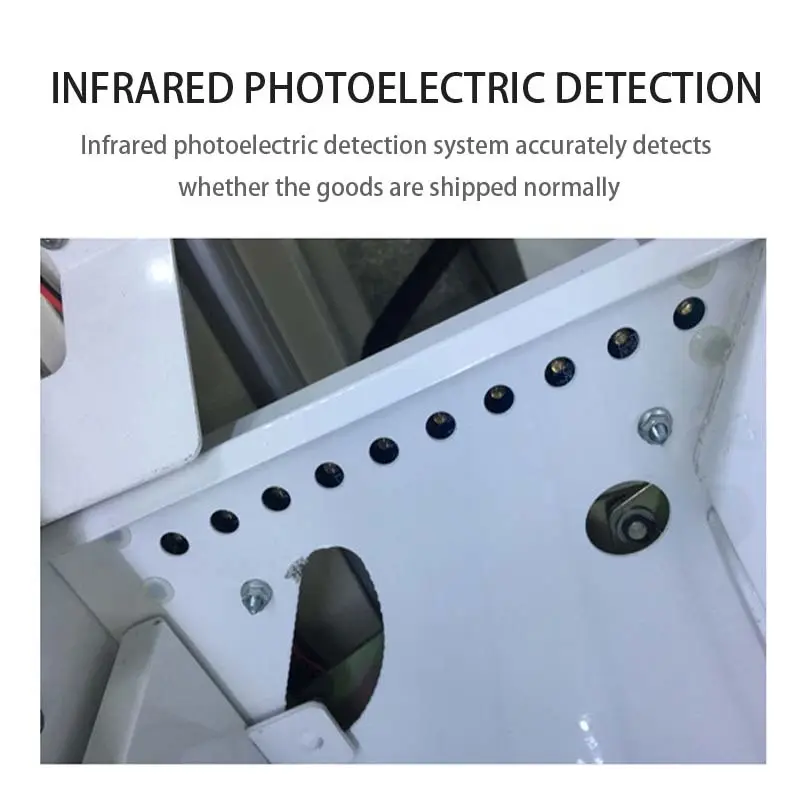

1. The production workmanship for Haloo recycling vending machine is of professionalism and sophistication. It is fabricated by cutting, grinding, honing, heat treating, surface polishing, and so on.

2. The additional functionality of this product further meets the customers needs.

3. This product is effectively applied in the industry with its compatible functions.

| Description | Index |

| Operation system | Android |

| Power & voltage | 110V-220V, 50/60HZ |

| Payment System | bill, coin, coin dispenser, and cashless payment. |

| Network Mode | GPRS(cloud monitor service) |

| Standard interface | MDB/DEX |

| Screen | Screen, touch screen with more size |

* We support customization. If you need more detail connect with us please.

◪ Belt delivery design, can sale more kind of goods.

◪ Durable Stainless steel keypad.

◪ Inside modular design, easy to update, operate and maintain.

◪ Shopping trolley function, more flexible to select goods.

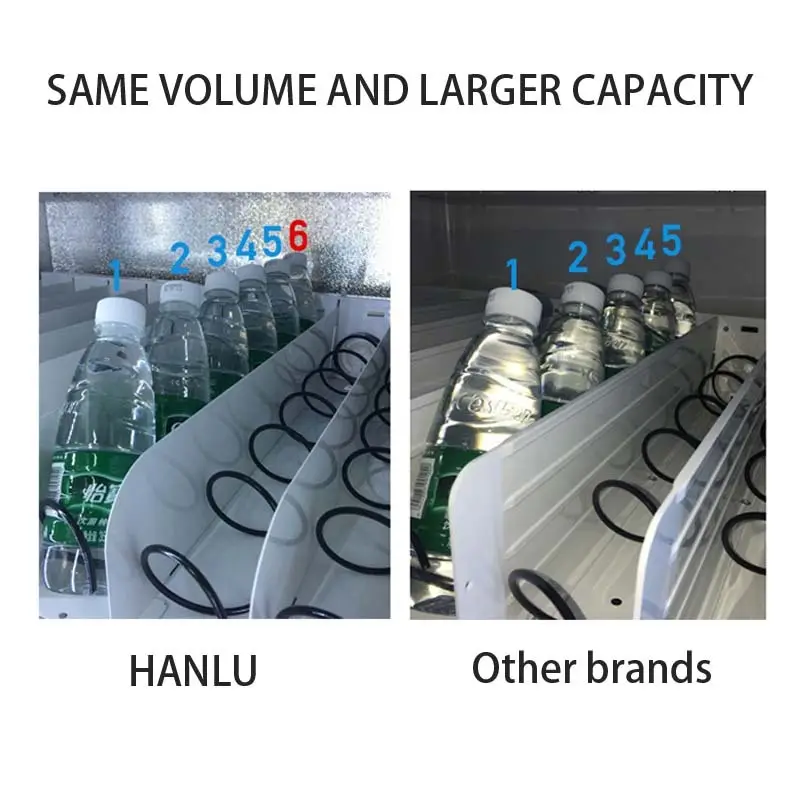

◪ High capacity to storage merchandise, more convenient.

◪ Salable goods: bottle packed/box packed/canned beverage, snack and condom, slave machine is available.

◪ Two lighting bars installed in two sides, attract consumers and convenient to shopping.

◪ Customized language display.

◪ Remote control system with management software, easy to check information and management in real time.

◪ The cargo port and inventory are completely isolated, with anti-theft device design.

◪ With power-off protection device, which can restore the date after restart.

◪ The powerful cloud service shows the sale information, running status of each vending machine from the internet anytime and anywhere.

◪ Support GPRS remote management system.

Company Features

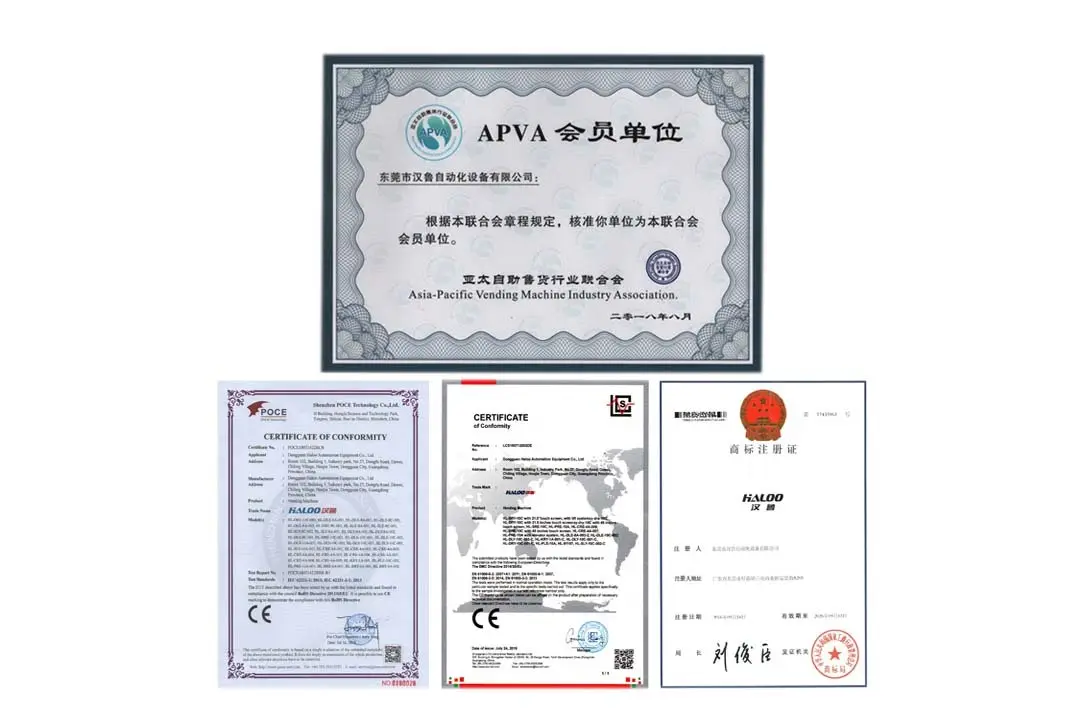

1. Based on manufacturing strength of [拓展关键词, Haloo Automation Equipment Co., Ltd has won the reputation and achieved success in the domestic markets.

2. We have hired incredible talents who are efficient and creative. They embrace the long-term vision and always being prepared for any eventualities. This enables them to always act flexibly to any changes in clients' needs and requirements.

3. Haloo Automation Equipment Co., Ltd will continue to perform strategic innovation and market creation. Please contact. Haloo Automation Equipment Co., Ltd always lists the needs of customers as the number one. Please contact. Haloo Automation Equipment Co., Ltd will continue to pay attention to business models and promote innovative spirit. Please contact. Efforts are being made for Haloo Automation Equipment Co., Ltd to be China's finest recycling machines manufacturer with good Global influence. Please contact.

PE PP & PET Waste Plastic Recycling & Washing Making Machine Production Line With Chinese Cheapest Factory Price

The line maybe consist of:

1. Belt conveyor: Transport materials

2. Screw feeder: Transport materials as well as rub them for surface clean

3. Metal detector bridge: For detection of NE metal and protect the granulator and washing components

4. Separation table: For separate the foreign materials manually

5. Crusher: Crush the materials to flakes of 15mm (two series: one for PET, one for PP/PE)

6. Hot washer: clean the materials in hot water, sometimes with some chemicals

7. Poaching tank: For separation of the flakes with a specific density of <1g/cbm from >1g/cbm or in contrast to separate the flakes with a specific of > 1g/cbm form <1g/cbm

( PET >1g/cbm and PP/PE <1g/cbm )

8. Friction washer:Surface clean the materials ( two series: one for PET, one for PP/PE)

9. Dewatering machine:

for mechanical surface drying of the material flakes with rotating roller ( two series: one for PET, one for PP/PE)

10. Blowing and drying system:

1. For discharging and transporting the material from the dryer 2. For final drying of the material to the necessary residual level for down stream material processing

11. Cyclone silo:

1. for separation of dust and fine material to achieve a better quality final product

2.Storagefor the final products

We are a professional manufacturer for various kinds of plastic machinery in Domestic & Aboard.

Any further details please contact me through email directly:

Sunny Ren

Sales7 at haosaite.com

WhatsApp & WeChat: +86 18863987837

Hope we can establish a win-to-win business cooperation.